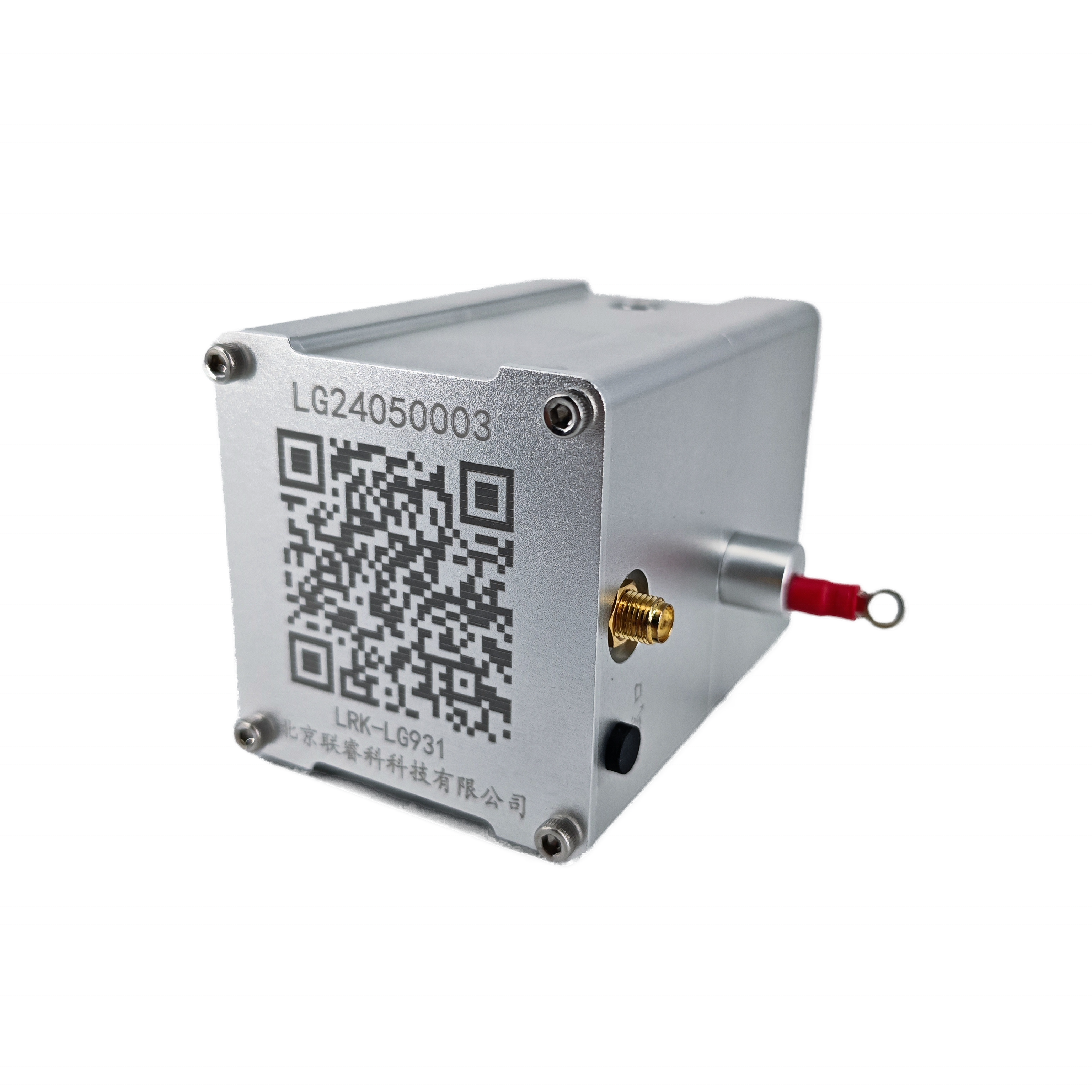

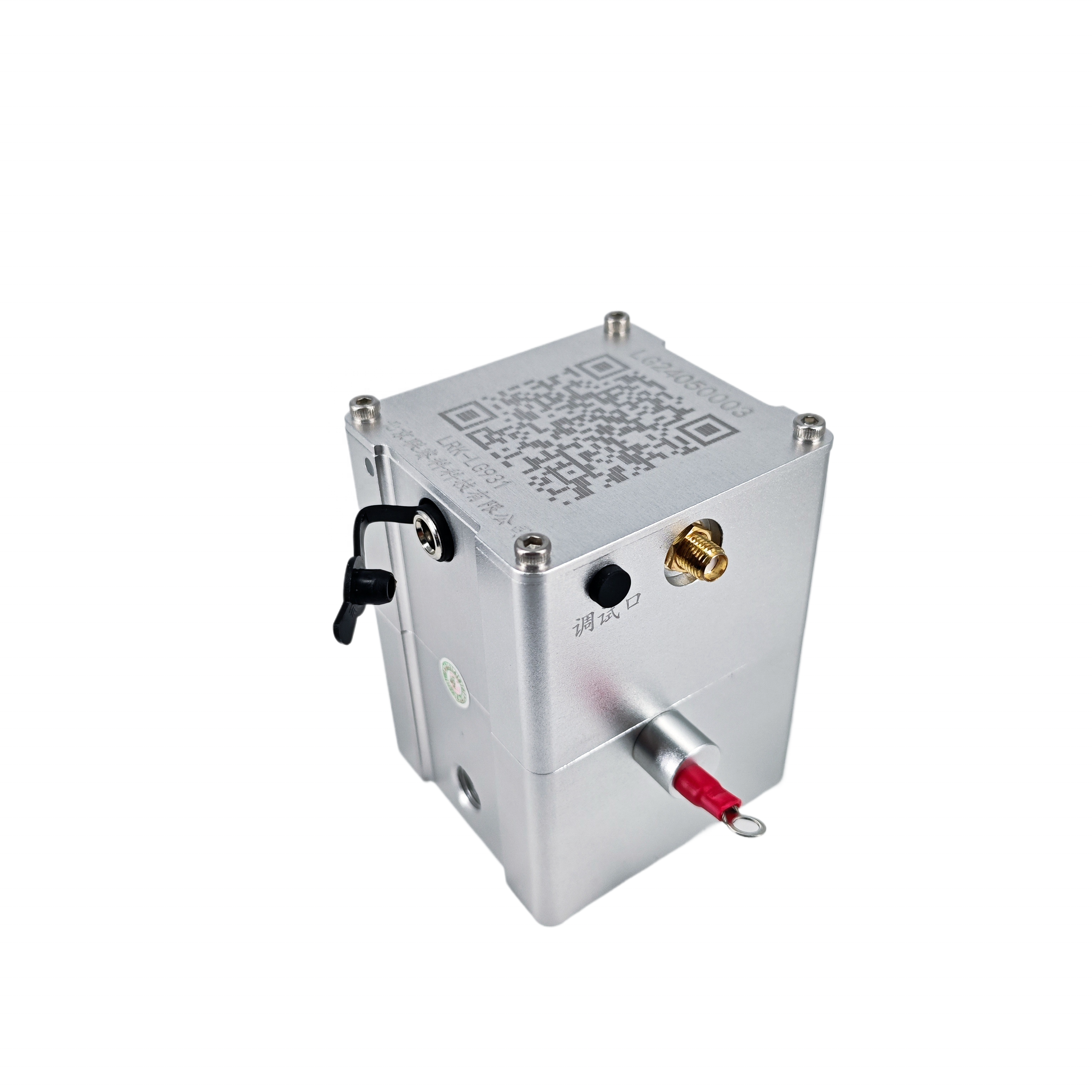

Product Overview

Wireless displacement sensor (crack gauge) is a resistive displacement sensor based on mobile Internet of Things transmission. Firstly, it adopts resistance sensor technology, which can accurately measure the small displacement of buildings or structures and monitor deformation in real time; Built in mobile IoT communication module, data transmission is achieved through wireless network, making it convenient for users to remotely monitor data and achieve real-time monitoring and remote control; Support automated monitoring projects, such as displacement monitoring, building deformation monitoring, and safety monitoring of old buildings, to reduce manual intervention and improve monitoring efficiency. Wireless displacement sensors (crack gauges) can not only help users monitor the displacement of buildings or structures in real time, but also detect potential safety risks in a timely manner, providing important reference data for engineering construction and daily monitoring. This product has a wide range of applications and provides users with a convenient and accurate automated monitoring solution.

Application Area

As a versatile monitoring instrument, wireless displacement sensors can play an important role in multiple fields, including civil engineering, geological engineering, water conservancy engineering, etc.

In the field of civil engineering, it is used for monitoring the displacement and crack changes of bridge structures in bridge monitoring; During the tunnel construction process, the displacement and crack situation of the surrounding structures of the tunnel; The deformation and cracking of buildings during long-term use.

In the field of geological engineering, it is used in landslide prone areas to monitor changes in landslide slopes in real time. It can also be used to monitor slope stability, timely detect slope displacement and crack propagation, and prevent slope instability from causing disasters.

In the field of hydraulic engineering, it is used to monitor the displacement, cracks, and other conditions of dams and embankments, ensure the safe operation of dams and embankments, timely detect and deal with potential safety hazards, and prevent and control disasters such as floods caused by instability.

Technical characteristics

*Adopting 4G single point transmission method

*Multiple power supply methods including built-in lithium battery, solar energy, and wind energy (optional) are used to ensure the ultra long operation of the sensor

*Ultra long standby, using autonomous sleep technology combined with automatic alarm emergency transmission to ensure data stability;

*Sampling autonomously sets the sampling frequency and transmission frequency to meet the real-time monitoring requirements.

| Project | Parameter |

|---|---|

| Measurement range | 0-150mm |

| Measurement accuracy | 0.1mm |

| Measurement method | Cable-type |

| Minimum sampling interval | 5 minutes |

| Minimum transmission interval | 10 minutes |

| Measurement method | Timed or real-time measurement |

| Transmission | 4G, WIFI, wired (optional) |

| Power supply method | Built in lithium battery, solar energy, 5V2A |

| Standby time | Related to sampling interva |

| Size | 100mmX140mmX35mm |

Layout principles and installation methods

Points should be set up on both sides of cracks, settlement joints, expansion joints, and at the junction of new and old buildings, as well as high and low buildings. Layout of crack points:

Arrange on both sides of the crack

Cross seam installation, or relative displacement position between measuring points and reference points